Leveraging Transportation Management Systems for End-to-End Logistics Efficiency

Understanding the Role of TMS in Modern Logistics Operations

Transportation Management Systems or TMS play a key role in managing the tricky balance between costs, delivery times, and dependable service across today's complex supply chains. When companies implement these systems, they typically see around 85% automation of everyday operations like choosing carriers and checking freight invoices according to the Industry Benchmark Report from 2024. What makes TMS really valuable is how they bring together different parts of the shipping process so everyone involved can work better together. This cuts down on mistakes made by hand-entered data and gives much clearer tracking information throughout the shipping journey. Businesses that have adopted TMS solutions find themselves dealing with about 18% fewer shipment delays caused by paperwork problems when compared to old fashioned manual methods. This kind of improvement makes a real difference in day to day operations for logistics managers.

AI-Driven Features That Optimize Carrier Selection and Routing

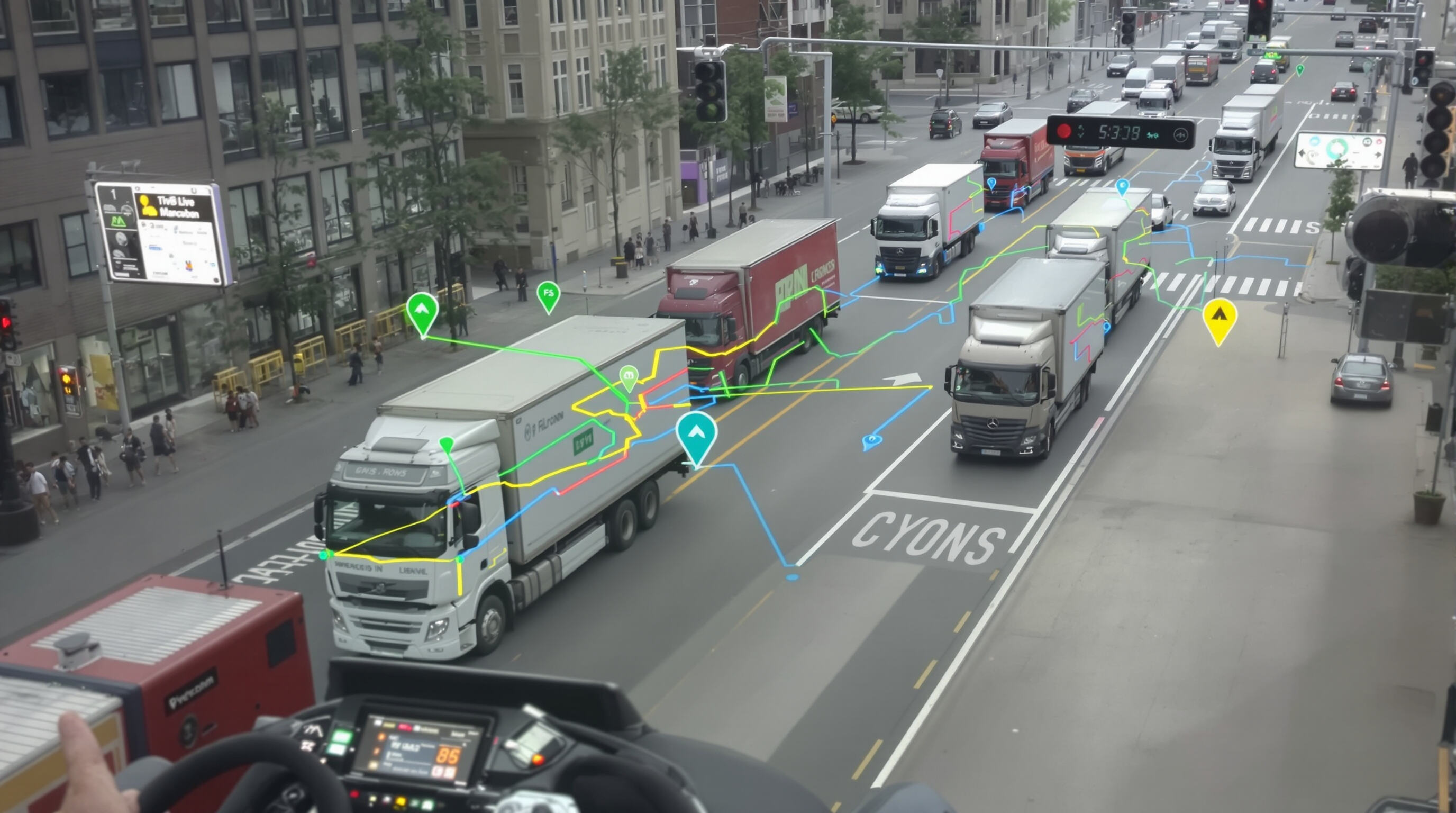

Transportation management systems powered by artificial intelligence look at past performance data, current capacity levels, and what's happening with market rates when suggesting the best carriers and shipping routes. The machine learning behind these tools considers all sorts of factors including fuel prices, whether drivers are available, and if bad weather might cause delays, then creates different routing scenarios based on those conditions. A major logistics company actually cut down on wasted driving distance by about 22 percent once they started using AI for their route planning. Beyond just saving money, these smart systems help businesses stay green too. They can match transportation choices with emission reduction targets, which makes it easier for companies to check off those important environmental, social, and governance requirements they face from investors and regulators around the world.

Step-by-Step Implementation of Logistics Software for Maximum ROI

- Assess workflow bottlenecks through process mapping to identify automation priorities

- Select a modular TMS that integrates with existing ERP/WMS systems

- Phase rollout by starting with high-impact areas like LTL procurement or invoice validation

- Train cross-functional teams on analytics dashboards for continuous improvement

Businesses following this structured approach typically achieve ROI within 8-12 months, realizing 30% gains in load consolidation efficiency and 15% reductions in freight spend. Regular system updates ensure compliance with evolving regulations such as electronic logging mandates.

Real-Time Route Optimization: Reducing Transit Time and Fuel Costs

How Real-Time Data Enhances Shipment Visibility and Responsiveness

GPS tracking combined with IoT sensors makes it possible to monitor shipments as they move along their routes, so logistics staff can jump into action when something goes wrong. If there's heavy traffic or bad weather hits a route, the system sends out automatic warnings to let dispatchers know what's happening. They can then send trucks down different roads before too much time gets lost. Studies show these systems cut down on delivery delays somewhere between 18% and 22%, which is pretty impressive. Plus customers get better info about where their stuff is because everything gets displayed on central dashboards that update regularly throughout the day.

Advanced Algorithms Powering Dynamic Route Adjustments

Route optimization software powered by artificial intelligence looks at traffic flows, road closures, and delivery time slots to figure out the best possible routes for vehicles. These systems get smarter over time as they analyze past performance data, spotting common problems such as rush hour bottlenecks or which carriers tend to cause delays. According to research published last year, businesses that implemented real time routing saw a reduction in wasted fuel from unnecessary detours by about 27 percent. What's more impressive is that they kept their deliveries on schedule around 95% of the time, even when faced with all sorts of disruptions in the supply chain network.

Integrating GPS and Traffic Data to Cut Fuel Consumption by 15-25%

When fleet managers combine real time GPS information with city traffic updates, they can steer clear of those areas where vehicles just sit idling. These dead zones eat up around 12 to maybe even 18 percent of yearly fuel expenses in cities alone. The routing systems tend to pick paths that have less stop and go action, which cuts down on how often engines need to start and stop unnecessarily. Less fuel burned is obviously important since gas typically takes up about a quarter of what companies spend on moving goods around. But there are other perks too. Vehicles last longer when they aren't constantly revving up and down, plus overall emissions drop off significantly as well.

Last-Mile Delivery Optimization for Faster, Cheaper Urban Fulfillment

Key Challenges in Last-Mile Logistics and Their Business Impact

Getting packages to their final destination in city centers remains a real headache for logistics companies. Traffic jams, missed deliveries, and customers wanting everything delivered today create constant problems. Studies show that delivering the last mile can eat up between 20 and 30 percent of overall shipping expenses because drivers get stuck in traffic or waste time waiting around. About one out of every six urban deliveries doesn't work on the first try either, usually because someone wrote down the wrong address or wasn't home when it arrived. All these issues cut into company profits by roughly 18% each year and really hurt brand loyalty too. Research from the 2024 Logistics Cost Benchmark indicates nearly half of all shoppers will stop buying from a company if they experience just one delayed shipment.

Micro-Fulfillment Centers and Alternative Delivery Models

Putting micro fulfillment centers within about 10 miles of busy city areas cuts down on travel time significantly, somewhere between 40 to maybe even 60 percent, while also reducing carbon emissions around 22%. Companies can save money too when they mix these local hubs with different delivery approaches like using crowd sourced drivers, locker systems for pickups, or scheduling deliveries during off peak hours. Some businesses report savings of roughly 30% on shipping costs this way. Take one big name retailer for instance who managed to pocket nearly $2.7 million each year after switching over to neighborhood based fulfillment and fine tuning those final mile routes that often eat up so much expense.

Measuring Success: KPIs for Last-Mile Performance Analytics

Key performance indicators include:

- On-Time Delivery Rate (target >98%)

- Cost Per Successful Delivery (ideal: <$6.50 in urban zones)

- Customer Satisfaction Score (benchmark: 4.7/5 via post-delivery surveys)

Real-time dashboards tracking these KPIs enable 19% faster issue resolution and improve route optimization accuracy by 12% week-over-week, supporting continuous improvement.

Data-Driven Logistics: Using Analytics to Reduce Costs and Improve Reliability

Harnessing Big Data for Smarter Load Planning and Carrier Management

Logistics teams leverage big data to analyze shipping patterns, traffic trends, and carrier performance. Predictive algorithms determine optimal trailer configurations 72 hours before departure, reducing unused space by 22% on average. According to a 2023 industry analysis, companies using dynamic load rebalancing lowered freight costs by 12-18%.

| Key Performance Metric | Impact on Savings |

|---|---|

| On-Time Delivery Rate | Reduces penalty costs by 8-15% |

| Fuel Efficiency | Lowers per-mile costs by 10-20% |

| Route Adherence | Cuts excess mileage by 25% |

Performance Metrics That Reveal Hidden Transportation Savings

Granular analytics uncover inefficiencies such as underperforming carriers, excessive idling, and suboptimal routing. Advanced platforms correlate weather data with delivery performance to reduce expedited shipping costs by 30% through proactive adjustments. Real-time monitoring of fuel use against terrain and traffic helps fleets save $0.14-$0.18 per mile.

From Insights to Action: Making Proactive Decisions with Real-Time Dashboards

Centralized dashboards take all that logistics data and turn it into real alerts that actually help out in the field. For instance, when roads get closed down, these systems can suggest alternate routes so managers fix problems before they really mess up service levels. Around 47 percent of issues get resolved this way according to recent numbers. Looking at a transportation report from last year, we see something interesting happening too. Companies using predictive models for delays saw customer satisfaction jump by nearly 20% because people got better estimates of arrival times. Top performers in the industry aren't stopping there though. They pair those insights with automatic carrier evaluations, which helps them keep their on-time deliveries consistently above 98.5% most of the time.

Strategic Load Planning and Multimodal Integration for Supply Chain Resilience

Maximizing Trailer Utilization to Lower Cost Per Mile

The problem of empty miles adds around 20 to 30 percent to overall trucking expenses according to CSCMP data from 2023. That makes getting better at filling trailers one of the most important ways companies can cut costs. Modern software for loading plans looks at how big shipments are, where their weight is distributed, and what order they need to go in so everything fits together safely without wasting space. These systems actually boost trailer usage by about 12 to maybe even 18 percentage points over what people can manage manually. And when trailers carry more goods for each mile driven, the cost drops right down across the board.

Combining Transport Modes to Balance Speed, Cost, and Reliability

When businesses combine rail transport, truck services, and intermodal options, they gain flexibility against rising fuel costs without sacrificing their ability to meet delivery deadlines. The rail system takes care of around three quarters of all long distance bulk shipments, doing so at roughly half the price tag compared to traditional highway transport methods. Meanwhile, trucks excel where precision matters most – getting goods from distribution centers right into customers' hands. Modern tracking systems help manage switches between different transportation types during unexpected roadblocks, making supply chains much tougher against disruptions. This kind of diversified approach keeps operations running smoothly even when market conditions shift unexpectedly.

Building Strong Carrier Relationships to Ensure On-Time Deliveries

Proactive collaboration with carriers—supported by diversified supplier networks—improves on-time delivery rates by 22% during peak seasons. Shared performance dashboards align expectations on loading times, tracking protocols, and exception management, which is especially critical for maintaining 98%+ reliability in temperature-sensitive shipments.

FAQs

1. What is a Transportation Management System (TMS)?

A Transportation Management System (TMS) is a software solution that helps logistics businesses manage and optimize the physical movement of goods. It deals with operations like carrier selection, route optimization, shipment tracking, and data analytics integration.

2. How does AI improve transportation management?

AI enhances transportation management by leveraging machine learning algorithms to optimize routes, select carriers, and predict potential disruptions. This leads to cost savings, improved delivery times, and better adherence to environmental targets.

3. What are some challenges of last-mile delivery?

Challenges in last-mile delivery include traffic congestion, incorrect delivery addresses, and narrow delivery time windows. These issues increase operational costs and can damage customer relationships if not managed effectively.

4. How can analytics reduce logistics costs?

Analytics can reveal inefficiencies such as unnecessary detours, underperforming carriers, and excessive idling. By using data-driven insights, companies can reduce fuel costs, improve delivery rates, and increase overall operational efficiency.

Table of Contents

- Leveraging Transportation Management Systems for End-to-End Logistics Efficiency

- Real-Time Route Optimization: Reducing Transit Time and Fuel Costs

- Last-Mile Delivery Optimization for Faster, Cheaper Urban Fulfillment

- Data-Driven Logistics: Using Analytics to Reduce Costs and Improve Reliability

- Strategic Load Planning and Multimodal Integration for Supply Chain Resilience

- FAQs